- You are here:

- Enterprise – E/E Systems Development

Enterprise – E/E Systems Development

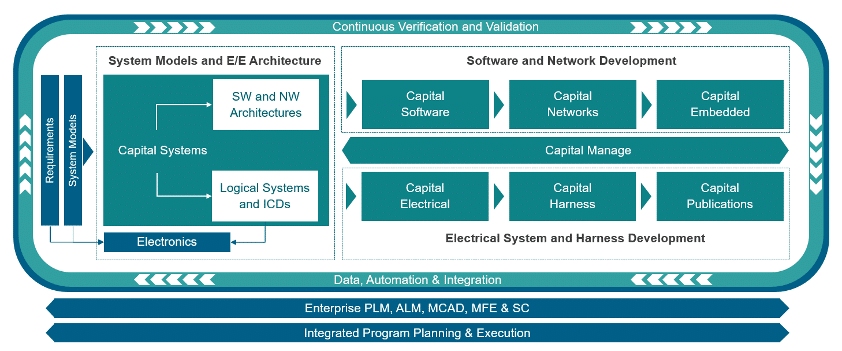

E/E SYSTEM DEVELOPMENT

A comprehensive E/E systems development solution for complex platforms in industries as diverse as automotive, aerospace, and adjacent industries

Source: Siemens Digital Industries Software

Modern E/E systems are characterized by a huge growth in complexity and depend on integrated electrical, electronic, and software systems for innovation while demanding robust verification and traceability. Many industries suffer from outdated, disconnected, and siloed product development methods. Companies are looking for new product development processes and tools that enable them to blur these boundaries across domains and through the product lifecycle. To address these challenges Siemens Digital Industries Software has developed the most comprehensive E/E systems development solution available to efficiently engineer today's smart products. It covers the design, manufacture, and service of electrical systems as well as encompassing E/E system and software architectures, network communications, and embedded software development.

Header Source: Siemens Digital Industries Software

More information

Fields marked with * are mandatory.

Fields marked with * are mandatory.

E/E Data Management & Integrations

Source: Siemens Digital Industries Software

Manage and integrate E/E systems data

Today's advanced E/E system development solutions need to deliver benefits such as managed supplier data exchange, data re-purposing, and process control. These and additional capabilities such as user, library, and release management are inherent to Capital.

- Integrate with common MCAD and PLM | ALM platforms, creating a digital thread with these adjacent applications

- An API enables the creation of forward-compatible extensions such as custom checks or rule decks, using Java plug-ins

- Library and design data can be automatically synchronized between multiple databases, and IT health monitoring ensures data integrity

Manage data, control processes, and use integrations to provide a comprehensive development flow

- E/E Tool & Data Integration

- E/E Collaboration & Supplier Integration

- E/E Configuration & Change Control

- E/E IP Capture & Re-use

- E/E Safety & Security

E/E Systems Definition & Optimization

Source: Siemens Digital Industries Software

Optimize electrical and electronic system architectures

It is necessary to optimize electrical and electronic system architectures against targets such as cost, weight, and network bandwidth. As architectural decisions have significant long term product impacts, being able to rapidly design, iterate, and optimize as early as possible in the development process leads to significant benefits all through the subsequent stages of bringing complex products to market.

- Reduce overall design time through rapid iteration and optimization of architectural concepts

- Increase engineering productivity with intuitive solutions

- Drive complex platform designs from multi-domain systems architecture and functional definitions supporting embedded software, networks, electrical, and electronics

- E/E Architecture Optimization & Verification

- E/E Function Definition & Consolidation

- Electrical, Electronics & Software Specification

Electrical Document Publication & Use

Source: Siemens Digital Industries Software

Rapid creation of interactive documentation & diagnostic publications

Reduce the cost and improve accuracy of publications by automating the creation of interactive documentation directly from engineering data. Capital accelerates service publication cycles by up to 80% through reuse of design data, and automation of tasks such as wiring diagram repartitioning, and graphical styling. It can increase technician efficiency by up to 40% using a vehicle-specific 3D-enabled interactive environment, improving customer satisfaction and reducing repeat repairs through a targeted diagnosis of problems. Publications can be automatically translated into multiple languages, and efficiently integrated into service portals.

Create interactive documentation directly from engineering data

- Design Change Documentation

- Electrical Diagnostics & Troubleshooting

- Technical Publications Creation

Electrical Systems Engineering

Source: Siemens Digital Industries Software

Design & integrate electrical systems into optimized product platforms

Optimize electrical system design, improve quality, and create integrated platform implementations. We help engineers design logical and wiring systems, as well as their integration, into a platform. Capital supports both the traditional interactive design approach and state-of-the-art generative design enabling best-in-class efficiency and quality. At all stages, the designs can be assessed for their efficacy and validated against requirements ensuring companies deliver the best products possible.

- Author logical and physical connectivity in a single environment

- Augment traditional interactive design with an integrated view of the platform to guide engineers as they make the best decisions possible

- Use generative design to automatically synthesize and verify the wiring for all configurations of the platform

- Electrical Optimization & Verification

- Electrical Systems Design & Simulation

- Electrical Systems Integration & Implementation

Embedded Software Design

Source: Siemens Digital Industries Software

Effectively specify, design, verify, and validate on-board software

Effectively design, test, and deploy on-board software by following a model-based approach in a common environment for system and software engineers. Connect the elements of your embedded software design processes and avoid rework costs by detecting errors early in the process. An architecture-centric approach allows you to define, enrich, analyze and simulate onboard software designs.

- Effectively design, test, & deploy on-board software by following a model-based approach

- Software Component Design & Simulation

- Software Component Implementation & Verification

- Software Architecture Development

- Software Component Design & Simulation

- Software Component Implementation & Verification

Embedded Software Implementation

Source: Siemens Digital Industries Software

In-vehicle AUTOSAR software solution for ECU development

Embedded software teams need to rapidly and efficiently develop and deploy software for automotive electronic control units (ECUs) to deliver in-vehicle features and functionality. The AUTOSAR standard is the framework to enable this efficient development of embedded application software in the context of vehicle system development. Capital VSTAR enhances the AUTOSAR standard while also satisfying cybersecurity and functional safety requirements, and is confirmed to support ISO 26262 ASIL D use cases.

- Quickly and efficiently develop and deploy AUTOSAR embedded software for automotive electronic control units (ECUs)

- Generative Software Configuration

- Software Verification Using Virtual ECUs

Harness Design & Engineering

Source: Siemens Digital Industries Software

Improve efficiency with model-based harness engineering

The manufacture of wiring harnesses is a hugely competitive industry facing shorter program launch cycles and increasing price pressure, coupled with increasing product and configuration complexity. To overcome these challenges companies are looking to:

- Reduce new product introduction times by leveraging digital data continuity and IP reuse

- Optimize designs and improve product quality by applying automation and simulation

- Improve efficiency by equipping people with the best in class technology

Capital's powerful design automation capabilities coupled with its model-based wiring harness engineering flow achieves all that and more. This helps harness manufacturers cut costs, improve product quality, and boost efficiency.

Gain a competitive advantage through advanced design automation

- Harness Costing

- Harness Design

- Harness Product Engineering

Harness Manufacturing Engineering

Source: Siemens Digital Industries Software

Leverage the digital twin to boost productivity & profits

The success of harness manufacturers is dependent upon their ability to accurately design, optimize and cost the manufacturing processes, labor, material, and resources required to produce harnesses. Capital contributes to an optimized digital twin comprising a validated harness model and a digitalized manufacturing process model. This can be leveraged to transform a company’s engineering, costing, and manufacturing performance ultimately boosting profits.

Optimize processes & improve manufacturing efficiency

- Harness Formboard Design

- Harness Manufacturing Documentation

- Harness Manufacturing Planning & Optimization

Network Design

Source: Siemens Digital Industries Software

Accelerate the design of validated networks with guaranteed delivery

Networks are a critical aspect of all modern vehicles and their design is interwoven with the design of embedded software and the electrical distribution system. New vehicle technologies require more complex network topologies to manage a significantly higher data throughput with more stringent constraints on timing. This requires an integrated, whole vehicle approach.

- Communications Implementation

- Communications Network Design

- Network Optimization & Verification

Fields marked with * are mandatory.

Fields marked with * are mandatory.

Speaker: Neil Rattray, OneSpin: A Siemens Business

Speaker: Neil Rattray, OneSpin: A Siemens Business  Speaker: Espen Tallaksen, EmLogic AS

Speaker: Espen Tallaksen, EmLogic AS  Speaker: Hans-Jürgen Schwender, TRIAS mikrolektronik

Speaker: Hans-Jürgen Schwender, TRIAS mikrolektronik Speaker: Faïçal Chtourou, Siemens EDA

Speaker: Faïçal Chtourou, Siemens EDA

Speaker: Joachim Müller, Efinix Inc

Speaker: Joachim Müller, Efinix Inc  Speaker: Dr. Markus Jäger, SciCaTec

Speaker: Dr. Markus Jäger, SciCaTec Speaker: David Lidrbauch, Siemens EDA (früher Mentor Graphics)

Speaker: David Lidrbauch, Siemens EDA (früher Mentor Graphics) Speaker: Eugen Krassin, LEC2

Speaker: Eugen Krassin, LEC2 Speaker: Harry Foster

Speaker: Harry Foster Speaker: Stefan Bauer

Speaker: Stefan Bauer Speaker: Tobias Baumann

Speaker: Tobias Baumann Speaker: Hans-Jürgen Schwender

Speaker: Hans-Jürgen Schwender Speaker: Frédéric Leens

Speaker: Frédéric Leens Speaker: Stefan Bauer

Speaker: Stefan Bauer Speaker: Nigel Woolaway

Speaker: Nigel Woolaway